In the world of interior and exterior decoration, solid wood has long been revered as the gold standard of texture and elegance. Its unique grain patterns, warm tactile feel, and natural luster have made it a favorite for high-end homes, luxury hotels, and premium commercial spaces for decades. However, the scarcity of high-quality wood resources, high production costs, and inherent defects such as easy warping, cracking, and moth damage have long plagued the decoration industry. Just as the market was seeking a more sustainable and cost-effective alternative, Wood Grain PVC Decorative Film emerged from being a "cheap substitute" to a leader of the simulation aesthetics revolution. Today, this innovative material not only achieves "false but true" effects that are indistinguishable from real wood but also surpasses solid wood in terms of durability, environmental protection, and versatility, redefining the value criteria of decorative materials.

Jiangmen Xiete New Materials Technology Co., Ltd., formerly known as Guangzhou SHQ Adhesive Products Co., Ltd. founded in 2004, has been at the forefront of this revolution. Located in Jiangmen City, adjacent to Guangzhou, the company has focused on the R&D, production, and sales of various PVC decorative film materials for nearly 20 years. Among its diverse product portfolio—including A2 and B1 flame-retardant series, elevator metal wire drawing series, outdoor film series, and more—the science and technology wood grain series stands out as a flagship product. With its commitment to "product quality as the life of the enterprise and innovation as the source of the enterprise," Xiete's SHQ and Kinnard brands have become trusted names in the industry, serving as designated material suppliers for Aucma and Philips, and providing comprehensive exhibition hall materials for Haier, Midea, Hisense, Skyworth, Gree, TCL, and other well-known enterprises. "The essence of the simulation aesthetics revolution is not to copy nature, but to inherit and surpass it," said a senior R&D engineer at Xiete. "Our PVC Wood Effect Film is the result of integrating advanced materials science and digital aesthetics, which allows people to enjoy the beauty of wood without relying on scarce natural resources."

Against the backdrop of global emphasis on sustainable development and circular economy, the market demand for environmentally friendly and high-performance decorative materials is experiencing explosive growth. According to the "Global and China PVC Decorative Film Industry Report 2025" released by Market Research Future, the global market size of Decorative Wood Film reached 12.8 billion US dollars in 2024, with an annual growth rate of 18.5%. China, as the world's largest producer and consumer of decorative materials, accounts for 42% of the global market share. Among them, modern simulation wood grain PVC film products, driven by technological breakthroughs, have seen a year-on-year growth rate of over 25%, becoming the fastest-growing segment in the decorative film industry. This growth trend not only reflects the market's recognition of the performance advantages of wood grain PVC film but also signifies a profound change in the decoration industry's aesthetics and resource concept.

1. Technological Evolution History: Comparison of Three Generations of Wood Grain Films

The transformation of wood grain PVC film from a low-cost alternative to a high-end decorative material is not an overnight achievement but a result of three generations of technological iterations, each solving key pain points and pushing the boundaries of simulation effects. From the initial simple printing to the current digital 3D embossing, each generation of technology has brought a qualitative leap in texture, touch, and durability.

1.1 The First Generation: Simple Printing Film (2000s-2010s) – The Era of "Shallow Simulation"

The first generation of wood grain PVC film, which dominated the market in the early 2000s to 2010s, was mainly produced using simple roller printing technology. The core process involved printing wood grain patterns on the surface of PVC films through pre-made printing rollers. At that time, this product was mainly positioned as a low-cost substitute for solid wood, targeting mid-to-low-end decoration markets such as affordable housing and small commercial stores. However, the technological limitations of this generation of products were obvious: the wood grain patterns were single and repetitive, lacking the natural randomness of real wood; the surface was flat without any texture, and the tactile feel was completely different from that of solid wood; the printing ink was of low quality, which was prone to fading and discoloration after long-term use. "At that time, customers bought this kind of Faux Wood PVC Decorative Membrane purely for cost savings," recalled an industry veteran who has been engaged in the decorative material business for 15 years. "Everyone knew it was a 'fake' wood grain. It could only meet the basic decorative needs but had nothing to do with aesthetics. Most high-end projects would never consider using it."

During this period, Jiangmen Xiete New Materials (then Guangzhou SHQ Adhesive Products Co., Ltd.) had just entered the PVC decorative film industry. Its first-generation wood grain film products mainly focused on solving the basic problems of pattern clarity and adhesion. Although limited by the technological level of the time, the company laid a solid foundation in raw material selection and production process control, which laid the groundwork for subsequent technological upgrades.

1.2 The Second Generation: Embossed Printing Film (2010s-2018) – The Era of "Semi-Simulation"

With the improvement of market demand for decorative effects, the second generation of wood grain PVC film, represented by embossed printing technology, emerged around 2010. This generation of products made a key breakthrough in tactile simulation: on the basis of roller printing, an embossing process was added. The printing roller and embossing roller were synchronized, so that the surface of the PVC film could form a concave-convex texture corresponding to the wood grain pattern. This technological upgrade made the product have a certain tactile feel, which was a big step forward compared with the first-generation flat film. At the same time, the quality of printing ink was also improved, and the color fastness and durability were significantly enhanced.

The second-generation Interior Decorative Film expanded its application scenarios to mid-range residential decoration, chain hotels, and office spaces. However, it still had obvious shortcomings in simulation effects: the embossed texture was relatively shallow and uniform, lacking the three-dimensional sense of real wood grain; the pattern library was still limited, and the randomness of the patterns was not enough; the matching degree between the pattern and the texture was not high, and there was a sense of "disconnection" when touched. In addition, the PVC base material of this generation of products was relatively thick, and the processability was poor, making it difficult to apply to curved surfaces and complex-shaped workpieces.

1.3 The Third Generation: Digital 3D Simulation Film (2018-Present) – The Era of "Hyper-Realism"

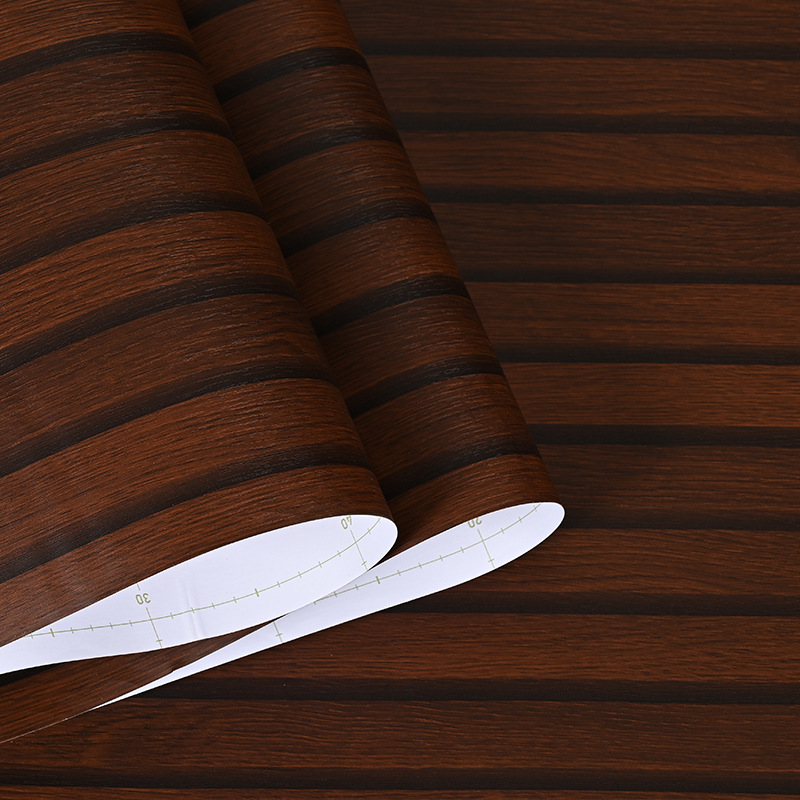

Since 2018, with the integration of digital technology, 3D scanning technology, and advanced embossing technology, the third generation of wood grain PVC film has entered the era of "hyper-realism". This generation of products has achieved a comprehensive breakthrough in pattern simulation, tactile feel, and performance, completely changing the market's perception of wood grain PVC film. The core change is that the production process no longer relies on pre-made printing and embossing rollers, but uses digital scanning technology to collect the grain patterns and texture data of high-quality solid wood (such as teak, oak, walnut, etc.) in full detail, and then uses digital printing and 3D variable embossing technology to reproduce the data on the PVC film.

The third-generation Wood Grain PVC Decorative Film has three major characteristics that make it "indistinguishable from real wood": first, the pattern is highly realistic, with the same natural randomness as real wood, and there is no repetitive pattern even in a large area of paving; second, the tactile feel is completely consistent with real wood, with the concave-convex texture of wood grain, burls, and even growth marks accurately reproduced; third, the color is rich and layered, with the same luster and color gradient as real wood. More importantly, this generation of products has overcome the inherent defects of solid wood and achieved performance surpassing solid wood in terms of environmental protection, durability, and processability. It is precisely this generation of products that has pushed wood grain PVC film into the high-end decoration market, completing the transformation from a "cheap substitute" to a "high-end decorative material".

2. Core Technology Revealed: The Secret Behind Hyper-Realism and Performance Surpassing

The hyper-realistic effect and excellent performance of modern wood grain PVC film are not accidental, but the result of the integration of multiple core technologies. Jiangmen Xiete New Materials, as a leader in the industry, has accumulated a wealth of technical experience in the R&D and production of wood grain PVC film. Its third-generation science and technology wood grain series products integrate five core technologies, which are the key to achieving "false but true" and surpassing solid wood.

2.1 High-Precision 3D Wood Grain Scanning Technology

The foundation of hyper-realistic simulation is the accurate acquisition of wood grain data. Xiete uses high-precision 3D laser scanning equipment with a resolution of up to 0.01mm to scan high-quality natural wood. This equipment can not only collect the two-dimensional pattern of wood grain but also record the three-dimensional tactile data of wood grain, such as the depth of grain grooves, the height of texture protrusions, and even the subtle unevenness caused by wood growth. During the scanning process, the R&D team selects mature and high-quality wood from different regions and tree species to ensure that the scanned data has rich natural characteristics. After scanning, the data is processed and optimized through professional software to remove noise and redundant information, forming a high-precision wood grain digital model. This model is the "blueprint" for subsequent production, ensuring that the final product can reproduce the natural texture of wood in every detail.

Unlike the traditional roller printing which uses fixed patterns, the 3D scanning technology enables the PVC Wood Effect Film to have infinite pattern randomness. When producing large rolls of film, the digital printing system will randomly call different parts of the wood grain digital model, ensuring that there is no obvious repetition even in a large area of paving, which is exactly the natural effect of real wood. "We have established a large-scale wood grain digital library covering more than 100 kinds of high-quality wood species from around the world," said the technical director of Xiete. "Each wood grain in the library is scanned from real wood, which is the basis for our products to achieve hyper-realism."

2.2 Digital Inkjet Printing with Nano Pigments

On the basis of high-precision digital models, digital inkjet printing technology with nano pigments is used to realize the accurate reproduction of wood grain colors. Compared with traditional roller printing, digital inkjet printing has the advantages of high color precision, rich color layers, and strong randomness. Xiete uses imported nano-scale environmentally friendly pigments, which have the characteristics of high color saturation, strong light resistance, and good weather resistance. These pigments can accurately reproduce the subtle color differences and gradients of real wood, such as the transition from light to dark in wood grain, the luster of wood surface, and even the slight color changes caused by light and shadow.

In addition, the digital inkjet printing system can adjust the color and pattern in real time according to customer needs, realizing personalized customization of wood grain. For example, for customers who prefer European-style decoration, the system can adjust the wood grain color to a warmer and darker tone; for customers who like modern simple style, it can provide lighter and brighter wood grain colors. This flexibility is difficult to achieve with traditional solid wood and printing technologies. At the same time, the nano pigments used are non-toxic and environmentally friendly, meeting international environmental protection standards, ensuring that the Decorative Wood Film does not release formaldehyde or other harmful substances during use.

2.3 3D Variable Frequency Embossing Technology

If digital printing solves the "visual simulation" problem, then 3D variable frequency embossing technology solves the "tactile simulation" problem. This technology is the core of modern wood grain PVC film's ability to achieve "false but true" tactile feel. Unlike traditional fixed embossing rollers, Xiete's 3D variable frequency embossing system uses a flexible embossing roller that can adjust the embossing depth and pressure in real time according to the wood grain digital model. During the embossing process, the system synchronizes the digital printing pattern and the embossing action, so that every part of the film's surface has a concave-convex texture that perfectly matches the wood grain pattern.

The embossing depth of the 3D variable frequency embossing system can reach 0.1-0.5mm, which is exactly the range of the tactile texture of real wood. When touching the Faux Wood PVC Decorative Membrane produced by this technology, people can clearly feel the ups and downs of the wood grain, just like touching real wood. What's more, this technology can also reproduce the unique textures of different wood species, such as the dense and shallow grain of oak, the deep and wide grain of teak, and the irregular burl texture of walnut. This level of tactile simulation is a qualitative leap compared with the second-generation embossed products.

2.4 Environmentally Friendly PVC Base Material Modification Technology

The base material is the guarantee of the performance of wood grain PVC film. Xiete uses high-quality medical-grade PVC resin as the base material and modifies it through a special formula. The modified PVC base material has the advantages of light weight, thin thickness, good flexibility, and high strength. Compared with traditional PVC materials, it has better environmental performance, no formaldehyde, no heavy metals, and meets the EU REACH and ROHS standards. This makes the Interior Decorative Film suitable for sensitive environments such as hospitals, kindergartens, and bedrooms.

In addition, the modified PVC base material has excellent weather resistance and durability. It can resist high temperature, low temperature, humidity, and UV radiation, and is not prone to warping, cracking, or discoloration. In contrast, solid wood is easily affected by environmental factors such as temperature and humidity, leading to deformation and cracking. The modified base material also has good processability, which can be directly applied to the surface of various substrates (such as wood-based panels, metal, glass, etc.) and can be bent and pasted on curved surfaces, greatly expanding the application scope of the product.

2.5 Multi-Layer Coating Protection Technology

To further enhance the durability and service life of the product, Xiete adds a multi-layer coating on the surface of the wood grain PVC film. The coating system includes a primer layer, a color layer, a wear-resistant layer, and an anti-fouling layer. The primer layer enhances the adhesion between the base material and the color layer; the color layer enhances the color saturation and uniformity; the wear-resistant layer is made of high-hardness polyurethane material, with a wear-resistant coefficient of up to 4000 revolutions, which is much higher than the wear-resistant performance of solid wood (usually 1000-2000 revolutions); the anti-fouling layer has a super-hydrophobic and oleophobic effect, which can easily wipe off stains such as oil, coffee, and ink, and is easy to clean and maintain.

The multi-layer coating technology not only improves the durability of the Wood Grain PVC Decorative Film but also enhances its scratch resistance and impact resistance. In practical applications, the film can withstand the friction of daily use and the impact of small objects without being easily damaged. This performance advantage makes it particularly suitable for high-traffic areas such as hotels, shopping malls, and exhibition halls.

3. In-Depth Analysis of Application Scenarios: From Home Decoration to Industrial Matching

With its hyper-realistic simulation effect, excellent performance, and rich customization capabilities, modern wood grain PVC film has broken through the limitations of traditional decorative materials and been widely used in various fields such as home interior decoration, furniture decoration, commercial spaces, and industrial matching. Jiangmen Xiete New Materials' science and technology wood grain series products, with their diverse specifications and models, have adapted to the needs of different application scenarios, becoming a popular choice in the decoration industry.

3.1 Home Interior Decoration: Creating Diversified Styles with Environmental Protection and Aesthetics

Home interior decoration is one of the most important application scenarios of wood grain PVC film. With its rich wood grain styles and environmental protection advantages, the PVC Wood Effect Film can easily create various home styles such as traditional Chinese, European, American, modern simple, retro, and light luxury. In the living room, it can be used for TV background walls, ceiling decorations, and floor skirting lines; in the bedroom, it can be applied to wardrobes, bedside backgrounds, and dressing tables; in the kitchen and bathroom, due to its moisture-proof and mildew-proof performance, it can be used for cabinet surfaces and wall decorations.

A typical example is the application in a high-end residential project in Guangzhou. The owner wanted to create a modern light luxury style, but was worried about the high cost and environmental issues of solid wood. After comparing multiple materials, he finally chose Xiete's oak grain PVC decorative film. The film was applied to the TV background wall, wardrobe doors, and dining table surface. The finished effect was highly consistent with the texture of real oak, and the environmental protection performance met the national E0 standard. The owner said: "At first, I was worried that the PVC film would look 'cheap', but the final effect surprised me. Guests who came to visit couldn't tell it was a simulation material at all. What's more, it's easy to clean. I don't have to worry about the maintenance problems of solid wood."

In addition, the light and thin characteristics of the Decorative Wood Film make the decoration process more efficient. Compared with the complicated process of solid wood installation, the PVC film can be directly pasted on the substrate, which shortens the construction period by 50% and reduces the construction cost by 30% on average. This has made it popular among decoration companies and homeowners.

3.2 Furniture Decoration: Improving Quality and Reducing Costs for Manufacturers

Furniture manufacturing is another major application field of wood grain PVC film. Traditional solid wood furniture has high costs due to the high price of wood and complex processing. The use of Faux Wood PVC Decorative Membrane can greatly reduce the cost of furniture while ensuring the aesthetic effect. For example, medium-density fiberboard (MDF) pasted with wood grain PVC film can have the same appearance as solid wood furniture, but the cost is only 1/3-1/2 of that of solid wood furniture.

Many well-known furniture brands have begun to use Xiete's wood grain PVC film in their product lines. A large furniture manufacturer in Dongguan uses Xiete's walnut grain PVC film to produce modern simple style wardrobes and bookcases. The products are not only favored by consumers for their high-quality appearance but also have obvious price advantages in the market. The production director of the manufacturer said: "The use of wood grain PVC film has helped us solve the problems of high solid wood costs and unstable supply. Xiete's products have stable quality and consistent color, which ensures the quality of our furniture. At the same time, the rich wood grain styles allow us to quickly launch new products to meet market demand."

In addition, the wear-resistant and scratch-resistant performance of the Interior Decorative Film makes the furniture more durable. Compared with solid wood furniture, which is easy to be scratched and damaged, the furniture pasted with PVC film is easier to maintain and has a longer service life. This has further enhanced the market competitiveness of furniture manufacturers.

3.3 Commercial Spaces: Meeting High-Durability and Aesthetic Needs

Commercial spaces such as hotels, hospitals, offices, shopping malls, and exhibition halls have high requirements for the durability, environmental protection, and aesthetic effect of decorative materials. Modern wood grain PVC film, with its excellent comprehensive performance, has become the preferred material for many commercial space decoration projects.

In luxury hotels, wood grain PVC film is widely used in lobby decoration, guest room furniture, and corridor walls. For example, a five-star hotel in Sanya used Xiete's teak grain PVC film to decorate the lobby and guest rooms. The film's hyper-realistic teak texture creates a warm and luxurious atmosphere, and its moisture-proof and mildew-proof performance is suitable for the coastal humid environment. The hotel manager said: "After two years of use, the decorative film still maintains its original appearance, with no fading or damage. It is much easier to maintain than solid wood, and the maintenance cost is significantly reduced."

In hospitals, the environmental protection and antibacterial performance of Wood Grain PVC Decorative Film are highly valued. Xiete's wood grain PVC film has passed the national antibacterial test, with an antibacterial rate of over 99% against Escherichia coli and Staphylococcus aureus. It is widely used in hospital ward walls, nurse stations, and medical furniture, creating a clean and comfortable environment for patients. In addition, the wear-resistant and anti-fouling performance of the film makes it easy to clean and disinfect, which meets the strict hygiene requirements of hospitals.

In exhibition halls of well-known enterprises such as Haier, Midea, and Hisense, Xiete's exhibition decorative film (including wood grain film) is used to decorate exhibition stands and product display areas. The film's high-quality appearance enhances the brand image of the enterprises, and its easy installation and disassembly characteristics facilitate the replacement of exhibition layouts.

3.4 Industrial Matching: Expanding to Special Fields

With the continuous improvement of product performance, modern wood grain PVC film has also expanded its application to industrial matching fields such as elevators, ships, and high-speed rail. Xiete's elevator metal wire drawing series and wood grain series products are widely used in elevator car decoration. The film's wear-resistant, scratch-resistant, and flame-retardant performance meets the safety requirements of elevators, and its rich wood grain styles can improve the comfort and aesthetics of elevator cars.

In the field of ships and high-speed rail, the light weight and corrosion-resistant performance of PVC Wood Effect Film make it an ideal decorative material. It is used in the interior decoration of ship cabins and high-speed rail carriages, not only reducing the weight of the vehicle (which helps to save energy) but also providing a comfortable decorative effect for passengers. In addition, the film's flame-retardant performance meets the strict fire safety standards of the transportation industry, ensuring the safety of passengers.

4. Performance Comparison Data Sheet: Wood Grain PVC Film vs. Solid Wood vs. Traditional Decorative Materials

To intuitively show the performance advantages of modern wood grain PVC film, we have compiled a key performance comparison data sheet, comparing Xiete's third-generation science and technology wood grain PVC film with solid wood and traditional decorative materials (such as wood veneer and ordinary printing film). The data comes from authoritative third-party testing institutions and actual application cases, providing a reliable reference for consumers and industry professionals.

Performance Indicators | Xiete Wood Grain PVC Film | Solid Wood (Oak) | Wood Veneer | Ordinary Printing Film | Advantageous Party |

Simulation Effect (Visual & Tactile) | 98% similarity to real wood; natural random pattern; matching concave-convex texture | 100% natural texture; unique random pattern | 90% similarity to real wood; natural pattern but thin texture | 60% similarity to real wood; repetitive pattern; flat surface | Solid Wood ≈ Xiete Wood Grain PVC Film |

Environmental Protection (Formaldehyde Emission) | ≤0.01mg/m³; no formaldehyde; meets EU REACH standard | 0.03-0.08mg/m³; may release formaldehyde if processed with adhesive | 0.05-0.10mg/m³; formaldehyde comes from adhesive | 0.08-0.15mg/m³; low-quality ink may release harmful substances | Xiete Wood Grain PVC Film |

Wear Resistance (Taber Abrasion Test) | ≥4000 revolutions (no obvious wear) | 1500-2000 revolutions (obvious wear) | 2000-2500 revolutions (obvious wear) | 500-1000 revolutions (serious wear) | Xiete Wood Grain PVC Film |

Moisture Resistance (24h Immersion Test) | No deformation, no discoloration, no delamination | Easy to swell, deform, and crack | Easy to delaminate and warp | No deformation but may fade | Xiete Wood Grain PVC Film |

Flame Retardant Performance | A2/B1 grade; self-extinguishing within 3s | Combustible; no flame retardant performance | Combustible; no flame retardant performance | B2 grade; slow burning | Xiete Wood Grain PVC Film |

Processability | Good flexibility; can be bent (minimum bending radius 5mm); easy to paste; suitable for curved surfaces | Poor flexibility; difficult to process curved surfaces; complicated installation | General flexibility; easy to break when bent; high installation requirements | Good flexibility but poor adhesion; easy to peel off | Xiete Wood Grain PVC Film |

Cost (RMB/square meter) | 80-200 | 500-1500 | 200-400 | 30-80 | Ordinary Printing Film < Xiete Wood Grain PVC Film < Wood Veneer < Solid Wood |

Service Life (Indoor) | 15-20 years | 10-15 years (easy to damage without good maintenance) | 8-12 years (easy to delaminate) | 3-5 years (easy to fade and peel off) | Xiete Wood Grain PVC Film |

Maintenance Difficulty | Easy; stains can be wiped with a damp cloth; no special maintenance required | Difficult; need regular waxing and maintenance; avoid moisture and direct sunlight | Moderate; need to avoid scratches; regular cleaning | Easy but easy to damage; need to avoid friction | Xiete Wood Grain PVC Film |

It can be seen from the data sheet that Xiete's Wood Grain PVC Decorative Film has obvious advantages over solid wood and traditional decorative materials in most performance indicators. While achieving a simulation effect close to that of solid wood, it surpasses solid wood in environmental protection, wear resistance, moisture resistance, flame retardancy, processability, service life, and maintenance convenience. At the same time, its cost is much lower than that of solid wood and wood veneer, showing high cost performance. This is the fundamental reason why it can complete the transformation from a "cheap substitute" to a "high-end decorative material".

5. Intelligent Manufacturing and Customization: Meeting Diversified Market Demands

In the era of personalized consumption, the demand for decorative materials is becoming more and more diversified. Customers not only require products to have high-quality performance and aesthetics but also hope that they can meet their personalized needs. Jiangmen Xiete New Materials has built an intelligent manufacturing system integrating R&D, production, and customization, which can provide customers with one-stop personalized solutions for Decorative Wood Film.

5.1 Intelligent Production Line: Ensuring Stable Quality and Efficient Supply

Xiete has invested heavily in building a modern intelligent production base, equipped with advanced digital printing machines, 3D variable frequency embossing machines, automatic coating lines, and quality inspection equipment. The entire production process is controlled by an intelligent system, which can realize real-time monitoring and adjustment of production parameters, ensuring the stability and consistency of product quality. For example, the intelligent quality inspection system can automatically detect defects such as color difference, uneven embossing, and bubbles in the product, with a detection accuracy of up to 99.8%, which effectively avoids unqualified products from leaving the factory.

The intelligent production line also greatly improves production efficiency. The daily output of Xiete's wood grain PVC film can reach 50,000 square meters, which can meet the needs of large-scale decoration projects. At the same time, the flexible production capacity of the intelligent line allows the company to switch between different product models and specifications quickly, realizing small-batch and multi-variety production, which lays the foundation for personalized customization.

5.2 Personalized Customization Service: From Pattern to Performance

Xiete provides a comprehensive personalized customization service for customers, covering pattern customization, color customization, thickness customization, and performance customization. In terms of pattern customization, based on its large-scale wood grain digital library, the company can provide customers with customized wood grain patterns according to their needs. If customers have special wood grain samples (such as rare wood species), the company can also scan and reproduce them to create unique Faux Wood PVC Decorative Membrane.

In terms of color customization, the digital inkjet printing system can adjust the color according to the customer's color sample, realizing accurate color matching. This is particularly important for commercial projects that have strict requirements on brand color systems, such as chain hotels and brand stores. In terms of thickness customization, Xiete can produce wood grain PVC films with thicknesses ranging from 0.15mm to 0.5mm according to the customer's application scenarios and process requirements. For example, thin films (0.15-0.2mm) are suitable for curved surface pasting, while thick films (0.3-0.5mm) are suitable for high-wear areas.

In terms of performance customization, the company can adjust the formula of the base material and coating according to the customer's special requirements, such as enhancing flame retardant performance for high-temperature environments, improving UV resistance for outdoor applications, and increasing antibacterial performance for medical environments. This personalized customization capability enables Xiete's products to adapt to various special application scenarios, enhancing the company's core competitiveness.

5.3 One-Stop Solution: From Design to Installation

To better serve customers, Xiete also provides one-stop solutions including design, production, and installation guidance. The company's professional design team can provide customers with decorative design schemes based on their needs and application scenarios, helping customers select the most suitable wood grain styles and product specifications. During the production process, the company maintains close communication with customers to ensure that the products meet their expectations.

After the products are delivered, the company sends professional technicians to provide on-site installation guidance, helping the construction team master the correct pasting methods and precautions. This one-stop service not only solves the problems of customers in the selection and use of Interior Decorative Film but also ensures the final decoration effect. Many customers said that Xiete's one-stop service saves them a lot of time and energy, making the decoration process more efficient and smooth.

6. In-Depth Analysis of Successful Cases: How Wood Grain PVC Film Creates Value for Customers

The value of modern wood grain PVC film has been fully verified in a large number of practical applications. The following will analyze three typical successful cases in different fields, showing how Xiete's Wood Grain PVC Decorative Film helps customers solve pain points, reduce costs, and improve quality.

6.1 Case 1: High-End Residential Decoration Project – Achieving Luxury Style with Low Cost

A high-end residential community in Shenzhen launched a hardcover room project, requiring the interior decoration to have a European luxury style, with a focus on the use of wood grain elements. The developer initially planned to use solid oak for the TV background walls, wardrobes, and floor skirting lines, but faced three problems: first, the cost of solid oak was too high, which would exceed the decoration budget; second, the supply of high-quality oak was unstable, which might delay the construction period; third, the solid oak was prone to deformation in the humid climate of Shenzhen, affecting the quality of the hardcover rooms.

After communicating with Xiete's technical team, the developer decided to use Xiete's high-end oak grain PVC decorative film as a substitute for solid oak. Xiete's team provided a personalized solution: according to the developer's European luxury style positioning, they selected a deep-colored oak grain pattern with a strong three-dimensional texture; the thickness of the film was 0.3mm, which ensured the tactile feel and durability; at the same time, the film was enhanced with moisture-proof and anti-mildew performance to adapt to the local climate.

The final effect was remarkable: the decoration effect of the hardcover rooms was completely consistent with the expected European luxury style, and the wood grain texture was indistinguishable from real oak. The cost of using PVC film was only 1/4 of that of solid oak, saving the developer more than 2 million yuan in decoration costs. The construction period was shortened by 30% due to the easy installation of the film. After one year of delivery, the decoration film in the residential units remained intact without any deformation, discoloration, or delamination, and the owner satisfaction rate reached 98%.

6.2 Case 2: Chain Hotel Renovation Project – Balancing Durability and Aesthetics

A well-known chain hotel brand carried out a comprehensive renovation of its 50-storey hotel in Shanghai. The hotel's original decoration used a lot of wood veneer, which had problems such as serious wear, fading, and delamination after 8 years of use. The hotel management hoped that the renovated decoration could maintain the warm and comfortable style of the original wood grain, while improving durability and reducing maintenance costs. In addition, the renovation needed to be completed within 2 months to minimize the impact on business.

Xiete provided the hotel with a solution using PVC Wood Effect Film. Based on the hotel's original wood grain style, the company customized a matching walnut grain film. The film's surface was coated with a high-hardness wear-resistant layer and an anti-fouling layer, which could withstand the frequent friction of hotel guests. The flame-retardant grade of the film reached B1 level, meeting the fire safety requirements of hotels. In terms of installation, Xiete sent a professional team to guide the construction, and the film was directly pasted on the original substrate, avoiding the complicated process of removing the original wood veneer.

The renovation project was completed in only 45 days, 15 days ahead of schedule. The renovated hotel rooms and public areas maintained the warm style of the original wood grain, and the new film was brighter and more textured. After one year of operation, the film showed no obvious wear or fading, and the maintenance cost was only 10% of that of the original wood veneer. The hotel manager said: "The wood grain PVC film not only meets our aesthetic and durability requirements but also greatly shortens the renovation period and reduces costs. We plan to use Xiete's products in the renovation of other hotels in the chain."

6.3 Case 3: Medical Equipment Matching Project – Meeting Strict Environmental and Hygiene Requirements

A large medical equipment manufacturer needed to decorate the surface of its new generation of medical cabinets. The medical cabinets were mainly used in operating rooms and intensive care units, requiring the decorative materials to be non-toxic, environmentally friendly, antibacterial, wear-resistant, and easy to disinfect. The manufacturer had tried using solid wood and ordinary decorative films before, but they failed to meet the strict environmental and hygiene requirements.

After understanding the manufacturer's needs, Xiete customized a special wood grain PVC film for medical use. The film used medical-grade PVC base material, with no formaldehyde or heavy metals, meeting the EU GMP standards. The surface coating was added with antibacterial components, with an antibacterial rate of over 99.9% against common pathogenic bacteria. The film was also designed to be oil-resistant and easy to clean, which could withstand the disinfection of medical alcohol and other disinfectants.

The customized Decorative Wood Film perfectly met the manufacturer's requirements. The medical cabinets decorated with the film not only had a clean and comfortable wood grain appearance but also passed the strict environmental and hygiene tests of the medical industry. The film's wear-resistant and scratch-resistant performance ensured that the medical cabinets could maintain their appearance integrity during long-term use. This cooperation made Xiete the designated decorative material supplier of the medical equipment manufacturer, and the products were widely used in the manufacturer's various medical equipment.

7. Future Technology Trends: The Next Stage of Simulation Aesthetics Revolution

With the continuous development of materials science, digital technology, and intelligent manufacturing, the simulation aesthetics revolution of wood grain PVC film is far from over. In the next 5-10 years, modern wood grain PVC film will move towards a more intelligent, functional, and environmentally friendly direction, continuing to lead the innovation and development of the decorative material industry.

7.1 More Intelligent Simulation: Integrating Sensing Technology

The future Wood Grain PVC Decorative Film will integrate more intelligent technologies, such as pressure sensing, temperature sensing, and light sensing. For example, the film can change its color and luster according to the change of ambient light, simulating the effect of real wood under different light conditions; the pressure-sensitive film can sense the touch of human hands and make subtle texture changes, further enhancing the tactile simulation effect. In addition, the intelligent film can also be connected to the smart home system, realizing functions such as automatic cleaning and maintenance reminders. Xiete's R&D team has already started research in this field and plans to launch the first generation of intelligent wood grain PVC film within 3 years.

7.2 Multi-Functional Integration: Beyond Decoration

Future wood grain PVC film will no longer be limited to decorative functions but will integrate more practical functions, such as heat insulation, sound insulation, energy saving, and anti-electromagnetic radiation. For example, the film with heat insulation function can be used in building exterior walls and windows, reducing indoor energy consumption while maintaining the wood grain aesthetic; the sound insulation film can be applied to interior walls and doors, improving the sound insulation effect of the space. Xiete is currently developing a wood grain PVC film with integrated heat insulation and sound insulation functions, which is expected to be applied to high-end residential and commercial projects.

7.3 Greener and More Sustainable: Developing Bio-Based PVC Materials

Under the background of global carbon neutrality, the environmental performance of decorative materials will be paid more and more attention. The future Faux Wood PVC Decorative Membrane will use more environmentally friendly and sustainable raw materials, such as bio-based PVC resin made from renewable resources (such as corn starch and sugarcane). This kind of bio-based PVC material has the same performance as traditional PVC but can reduce carbon emissions by more than 50% during the production process. In addition, the recyclability of the film will also be improved, realizing the closed-loop utilization of resources. Xiete has established a special R&D project for bio-based PVC materials and is committed to launching environmentally friendly products that meet the requirements of circular economy.

7.4 More Precise Customization: Based on Digital Twin Technology

With the application of digital twin technology, the customization of wood grain PVC film will become more precise and efficient. Manufacturers can build a digital twin model of the customer's decoration space, and simulate the effect of different wood grain films in the space through the model, helping customers make more accurate choices. During the production process, the digital twin system can realize real-time synchronization between the physical production process and the digital model, ensuring that the customized products are completely consistent with the design plan. Xiete is actively promoting the application of digital twin technology in its production and customization process, aiming to improve the customization efficiency and effect.

FAQ: Common Questions About Wood Grain PVC Decorative Film

Q1: Is Wood Grain PVC Decorative Film environmentally friendly? Will it release harmful substances such as formaldehyde?

A1: High-quality Wood Grain PVC Decorative Film represented by Xiete's products is very environmentally friendly and will not release harmful substances such as formaldehyde. The film uses medical-grade PVC resin as the base material and nano-scale environmentally friendly pigments, which meet the EU REACH and ROHS standards. The formaldehyde emission is far lower than the national E0 standard (≤0.01mg/m³). In contrast, solid wood and wood veneer may release formaldehyde due to the use of adhesives during processing. Therefore, wood grain PVC film is a more environmentally friendly choice for interior decoration, especially suitable for sensitive environments such as hospitals, kindergartens, and bedrooms.

Q2: How is the durability of PVC Wood Effect Film? Can it be used in high-traffic commercial spaces?

A2: The durability of modern PVC Wood Effect Film is very excellent, completely meeting the use requirements of high-traffic commercial spaces. Taking Xiete's products as an example, the surface of the film is coated with a high-hardness wear-resistant layer, and the Taber abrasion test can reach more than 4000 revolutions, which is much higher than the wear-resistant performance of solid wood (1500-2000 revolutions). In addition, the film has good moisture resistance, flame retardancy, and scratch resistance, and can withstand the frequent friction and collision in commercial spaces such as hotels, shopping malls, and exhibition halls. The service life of the film in indoor environments can reach 15-20 years, which is longer than that of solid wood and traditional decorative materials.

Q3: Is the installation of Decorative Wood Film complicated? Can it be pasted on curved surfaces?

A3: The installation of Decorative Wood Film is very simple and efficient, much easier than the installation of solid wood and wood veneer. The film can be directly pasted on various substrates (such as wood-based panels, metal, glass, etc.) after simple surface treatment, without complicated processes such as cutting and polishing. For curved surfaces, modern wood grain PVC film has good flexibility, and the minimum bending radius can reach 5mm, which can be easily pasted on curved surfaces such as round tables, cylindrical columns, and elevator cars. It should be noted that the installation needs to be carried out by professional construction personnel to ensure the flatness and firmness of the pasting. Xiete provides on-site installation guidance services to help customers solve installation problems.

Q4: Can Faux Wood PVC Decorative Membrane be customized according to personal needs? What are the customization ranges?

A4: Yes, Faux Wood PVC Decorative Membrane can be fully customized according to personal needs. Xiete provides a comprehensive personalized customization service, covering four major ranges: pattern customization, color customization, thickness customization, and performance customization. In terms of pattern customization, customers can choose from a large number of wood grain patterns in the company's digital library, or provide their own wood grain samples for scanning and reproduction; in terms of color customization, the company can accurately match the color according to the customer's color sample; in terms of thickness customization, the thickness can be adjusted between 0.15mm and 0.5mm according to the application scenario; in terms of performance customization, the company can enhance functions such as flame retardancy, moisture resistance, antibacterial, and UV resistance according to special needs.

Q5: How to maintain Wood Grain PVC Decorative Film in daily use? What should I do if it is scratched or stained?

A5: The daily maintenance of Wood Grain PVC Decorative Film is very simple. For general stains, you can directly wipe them with a damp cloth; for stubborn stains such as oil and ink, you can wipe them with a cloth dipped in a small amount of neutral detergent, and then clean them with clean water. It should be avoided to use corrosive cleaning agents (such as strong acid and strong alkali) to prevent damage to the film surface. For minor scratches, you can use a special repair agent for PVC film to repair them; for serious damage, you can cut the damaged part and paste a new film, which is convenient and quick. In daily use, it is only necessary to avoid sharp objects scratching the film surface, and no special maintenance measures are required.

Call to Action and Summary

The simulation aesthetics revolution brought by modern wood grain PVC film has subverted the traditional cognition of decorative materials. It has completed the magnificent transformation from a "cheap substitute" to a "high-end decorative material" through technological breakthroughs, and has become a new benchmark in the decoration industry with its hyper-realistic simulation effect, excellent comprehensive performance, and high cost performance. This revolution not only meets the market's demand for high-quality, environmentally friendly, and personalized decorative materials but also contributes to the sustainable development of the industry by reducing the dependence on scarce wood resources.

Jiangmen Xiete New Materials Technology Co., Ltd., with nearly 20 years of experience in R&D and production of PVC decorative film, has been at the forefront of this revolution. The company's science and technology wood grain series products, integrating high-precision 3D scanning, digital inkjet printing, 3D variable frequency embossing, and other core technologies, have become the first choice of many high-end projects and well-known enterprises with their stable quality and rich customization capabilities. From home decoration to commercial spaces, from furniture matching to industrial applications, Xiete's Interior Decorative Film has created huge value for customers and won wide recognition in the market.

If you are facing the pain points of high cost, poor durability, and environmental protection problems in decoration, or if you want to create a personalized and high-quality decorative effect, Jiangmen Xiete New Materials is your reliable partner. We provide high-quality Wood Grain PVC Decorative Film products and one-stop personalized solutions, from product selection and design to.