As carbon neutrality commitments accelerate worldwide, the construction and interior decoration industries are facing unprecedented pressure to reduce environmental impact without sacrificing aesthetics or performance. From residential renovation to large-scale commercial projects, materials are being reassessed through the lens of sustainability. Against this backdrop, Eco-friendly Wood PVC Film has emerged as a compelling alternative to traditional wood-based finishes, offering a balance between natural appearance and environmental responsibility.

Jiangmen Xiete New Materials Technology Co., Ltd., located near Guangzhou, has been deeply involved in this transformation. With a comprehensive portfolio covering wood grain, marble, fabric, metallic, and outdoor decorative films, the company provides advanced solutions that meet modern design expectations while aligning with global carbon reduction strategies. By integrating Sustainable Decorative Film, Recyclable Wood Grain Film, Green Building Materials, and Low Carbon PVC Film technologies, Xiete is helping the industry move closer to measurable carbon neutrality.

1. Market Challenges: Carbon Pressure and Material Transformation

Traditional interior materials, especially solid wood and natural veneers, carry a high environmental cost due to deforestation, long growth cycles, and energy-intensive processing. These issues are increasingly incompatible with carbon reduction targets. As a result, architects and developers are seeking Green Building Materials that reduce resource consumption while maintaining design authenticity.

Consumers are also more informed than ever. Health, indoor air quality, and sustainability have become decisive purchasing factors, driving demand for Sustainable Decorative Film solutions that are formaldehyde-free, antibacterial, and suitable for long-term indoor use. In this context, Eco-friendly Wood PVC Film stands out by significantly lowering reliance on natural timber while delivering consistent visual quality.

At the policy level, governments and certification systems are encouraging the use of Low Carbon PVC Film and recyclable materials, further accelerating market adoption.

2. Technological Innovation: How Wood Grain PVC Films Reduce Carbon Footprint

Carbon reduction in decorative materials is achieved not through a single innovation, but through a system-level approach. Modern Low Carbon PVC Film production optimizes energy consumption, reduces waste, and shortens manufacturing cycles compared to traditional wood processing.

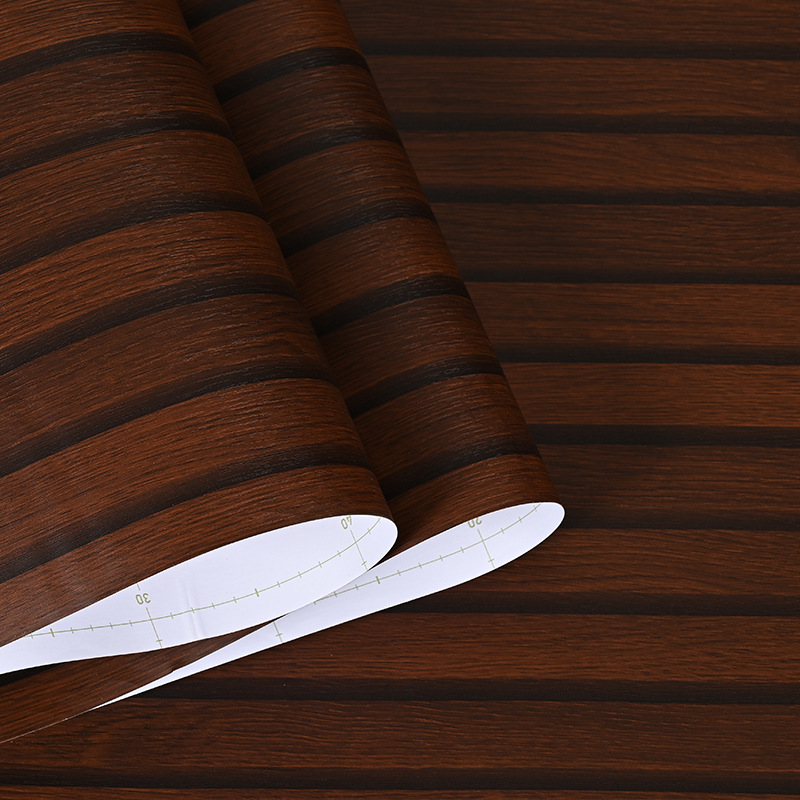

Advanced printing and embossing technologies allow Recyclable Wood Grain Film to replicate natural wood textures with remarkable accuracy, eliminating the need for logging while ensuring stable quality across batches. At the same time, lightweight structures reduce transportation emissions, reinforcing the role of Eco-friendly Wood PVC Film in global carbon management.

By incorporating recyclable substrates and optimized formulations, Sustainable Decorative Film systems support circular material flows, making them increasingly compatible with next-generation Green Building Materials standards.

3. Application Scenarios: Sustainable Design in Real Projects

In residential interiors, Eco-friendly Wood PVC Film is widely used on cabinets, doors, wardrobes, and wall panels, delivering warm, natural aesthetics without the environmental burden of solid wood. Its durability and easy maintenance make it particularly suitable for long-term use.

Commercial spaces such as hotels, offices, and shopping malls increasingly specify Sustainable Decorative Film to meet sustainability targets while ensuring consistent visual identity across multiple locations. For public infrastructure projects, Green Building Materials with A2 and B1 fire-retardant ratings are essential, making advanced PVC films a practical choice.

In renovation projects, Recyclable Wood Grain Film allows existing surfaces to be upgraded quickly, reducing demolition waste. Meanwhile, Low Carbon PVC Film solutions are favored in large-scale developments where lifecycle carbon performance is closely monitored.

4. Performance and Carbon Impact Comparison

Industry Performance Comparison Table

| Indicator | Traditional Wood Veneer | Eco-friendly Wood PVC Film |

| Raw Material Source | Natural timber | Engineered synthetic |

| Carbon Emissions | High | Reduced |

| Visual Consistency | Variable | Stable |

| Fire Performance | Limited | A2 / B1 optional |

| Maintenance Cost | High | Low |

| Recyclability | Low | Supported by Recyclable Wood Grain Film |

Carbon Reduction Insight Table

| Factor | Impact |

| Reduced deforestation | Supports Green Building Materials policies |

| Lightweight transport | Lowers emissions with Low Carbon PVC Film |

| Long service life | Enhances Sustainable Decorative Film value |

| Recyclable systems | Promotes circular economy |

These data points demonstrate why Eco-friendly Wood PVC Film is increasingly selected for projects aligned with carbon neutrality objectives.

5. Frequently Asked Questions (FAQ)

Q1: How does this material help reduce carbon emissions?

By replacing natural wood and optimizing production efficiency, Low Carbon PVC Film significantly lowers overall emissions.

Q2: Is the appearance comparable to real wood?

Yes. Modern Recyclable Wood Grain Film technologies closely replicate natural textures and tones.

Q3: Can it meet green building certification requirements?

Many projects using Green Building Materials incorporate certified Sustainable Decorative Film products.

Q4: Is it safe for indoor environments?

Absolutely. Eco-friendly Wood PVC Film is formaldehyde-free, antibacterial, and suitable for sensitive spaces.

Q5: What happens at the end of its lifecycle?

Selected products can re-enter recycling streams, reinforcing the sustainability value of Recyclable Wood Grain Film.

Conclusion: A Practical Path Toward Carbon Neutral Interiors

Achieving carbon neutrality in the built environment requires realistic, scalable solutions. By reducing reliance on natural timber, optimizing production efficiency, and enabling recycling, Eco-friendly Wood PVC Film represents a meaningful step forward. Combined with Sustainable Decorative Film systems, Recyclable Wood Grain Film technology, and certified Green Building Materials, these products provide designers and developers with a viable path toward lower-carbon interiors.

As demand for Low Carbon PVC Film continues to grow, materials that balance aesthetics, performance, and environmental responsibility will define the future of interior decoration.

Call to Action

Jiangmen Xiete New Materials Technology Co., Ltd. welcomes architects, developers, and distributors seeking sustainable surface solutions.

Contact us today to request samples or customization and explore how eco-friendly wood grain PVC films can support your carbon neutrality goals.