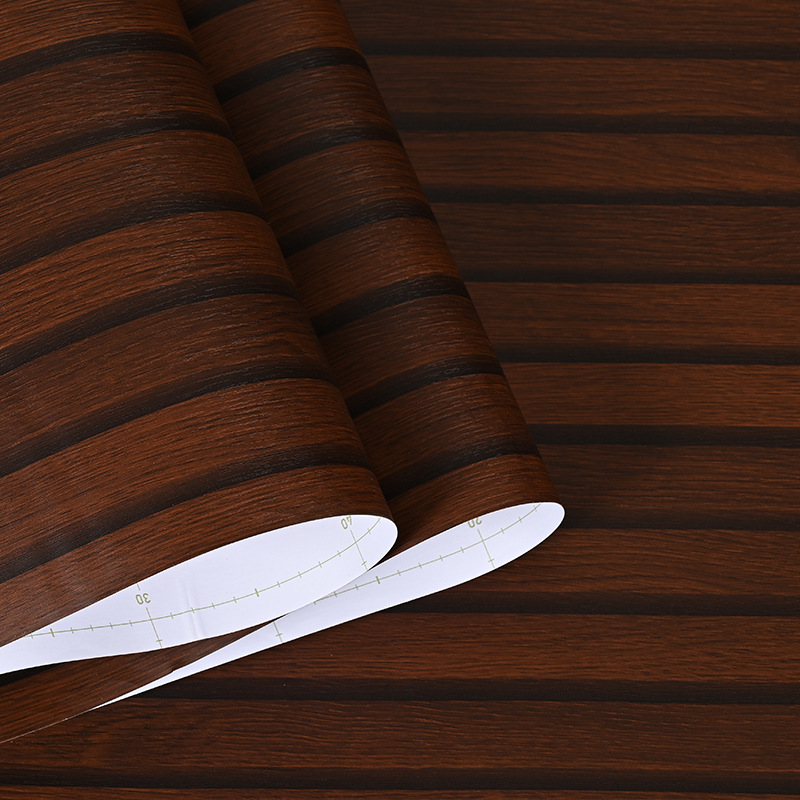

In the global decorative materials market, Wood Grain PVC Film has become a popular choice across furniture, interior design, construction, automotive, and commercial decoration sectors. As “eco-friendly design” and “premium surface finishes” dominate consumer preferences, overseas buyers are demanding higher standards of performance, environmental certification, and supply stability.

However, amid rising material costs and ongoing logistics disruptions, global purchasers are asking a key question: how to secure a supplier that combines stable quality, certified sustainability, and cost efficiency?

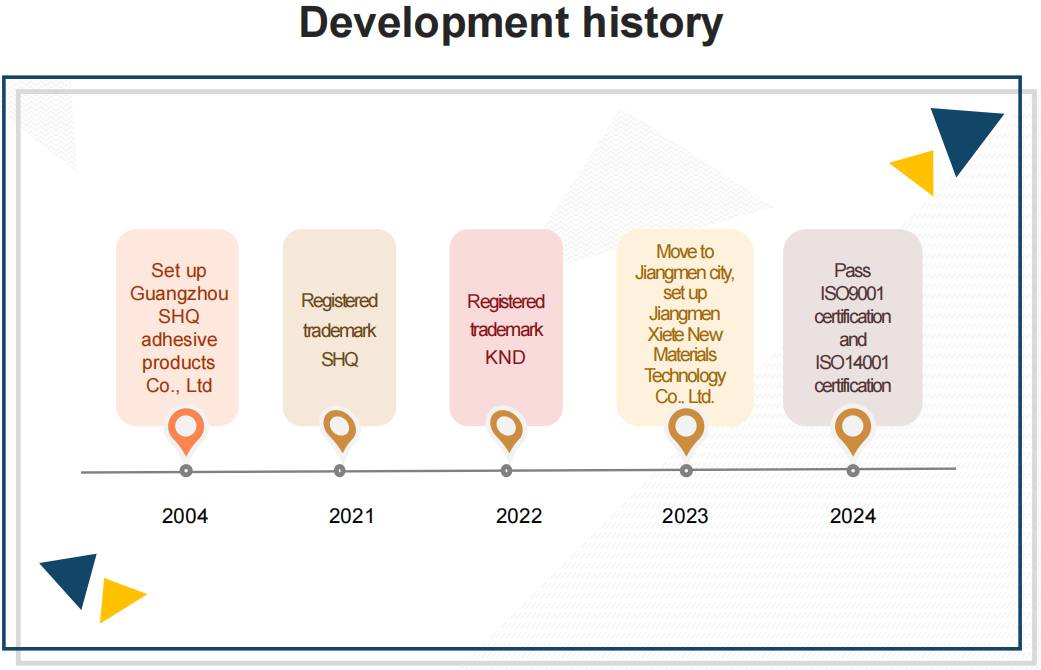

In China, that answer is increasingly defined by manufacturers with full-chain production capabilities. Among them, Jiangmen Xiete New Materials Technology Co., Ltd. (formerly Guangzhou SHQ Adhesive Products Co., Ltd.), based in Jiangmen near Guangzhou, stands out as a new leader in the Nature Wood PVC Decorative Film industry — mastering proprietary material development, large-scale production, and strict quality control from end to end.

1. Global Industry Pain Points: The Turning Point from OEM to Independent Manufacturing

Over the past decade, the global PVC decorative film market has grown at an average annual rate of 7.4%. Yet, with the tightening of EU E1 formaldehyde limits and the U.S. CARB compliance requirements, traditional suppliers have exposed three major weaknesses:

| Global Pain Points in PVC Decorative Film | Description | Impact on Buyers |

|---|---|---|

| Unstable base materials | Dependent on external calendering plants; high shrinkage and batch variation | Wrinkling, edge lifting, and inconsistent finish |

| Long lead times | Multi-party coordination delays production | Increased inventory and project risk |

| Weak environmental compliance | Lack of ROHS, REACH, or VOC certification | Market access barriers in Europe & the U.S. |

This explains why more international wholesalers are turning to Chinese factories that control Our proprietary base material and offer full-chain integration.

2. China’s Full-Chain Advantage: From Raw Material to Global Wholesale Power

(1) Proprietary Base Material — Quality Begins at the Source

Unlike most competitors who rely on third-party calendering suppliers, Xiete operates German-imported calendering production lines and independently develops Our proprietary base material.

This enables precise control of shrinkage, maintaining it below 0.3%, far better than the 0.5%–0.8% industry average. The resulting Low-shrinkage Wood Grain PVC Film maintains flatness and adhesion even under high temperature and humidity — ideal for cabinets, wall panels, furniture, and outdoor decoration.

“We believe the real stability of a film begins with its base, not its printing.”

— Technical Director, Jiangmen Xiete

(2) Large-Scale Production — 40,000 m² Factory Powering Global Supply

Xiete operates a 40,000-square-meter modern facility with multiple high-speed printing, embossing, and laminating lines, producing over 2,000 tons annually and shipping up to 40 containers per month.

This Large-scale wholesale Wood Grain PVC Film capacity ensures supply security and efficiency for international wholesalers:

Minimum order as low as 3,000 meters for flexible procurement.

7–15-day delivery time, far faster than the 45–60 days typical in Europe;

OEM and logo customization available for brand differentiation.

(3) End-to-End Quality Control — Traceable from Powder to Roll

Xiete enforces a 10-step quality management system, ensuring full traceability and consistency:

Raw materials: Japanese imported PVC powder for superior purity and elasticity;

Color accuracy: Multi-point testing with ΔE ≤ 0.5%;

Certifications: ISO 9001, ROHS, REACH, and E1-grade formaldehyde compliance;

Product type: Certified as Environmentally certified Wood Grain PVC Film.

Such rigorous control has earned Xiete partnerships with top brands including Haier, TCL, Midea, Philips, and Gree.

3. Wholesale Value: Efficient, Cost-Saving, and Reliable

Xiete’s strength lies not only in quality, but in delivering real value to wholesale partners:

Cost efficiency: Direct-from-factory pricing, 20–30% lower than European suppliers;

Supply reliability: Independent calendering and coating lines ensure Stable supply of Wood Grain PVC Film all year round;

Customization flexibility: Multiple sizes, textures, and thickness options;

Brand support: Private labeling, catalog design, and marketing assistance.

The company currently supplies clients across India, Russia, and the UAE with tailor-made wood grain films. Thanks to consistent performance and stable quality, it has achieved an 85% repurchase rate over three years, becoming a trusted partner for regional furniture producers.

4. Industry Data Insights

| Key Indicator | Xiete Factory | Global Average | Competitive Advantage |

|---|---|---|---|

| Base material control | In-house production | Outsourced | 30% lower shrinkage |

| Color variance | ≤0.5% | ≤1% | Higher visual consistency |

| Monthly capacity | 40 containers | 10–15 containers | Strong wholesale supply |

| Certifications | ISO9001 / ROHS / REACH | Partial coverage | Full compliance |

| Wholesale price | 20–30% lower than EU | — | Strong price competitiveness |

| Lead time | 7–15 days | 30–45 days | 2× faster delivery |

5. Global Buyers’ FAQ

Q1: Can your Wood Grain PVC Film be used outdoors?

Yes. Our environmentally certified Wood Grain PVC Film is UV-resistant and weatherproof, suitable for facades, outdoor furniture, and signage.

Q2: Do you accept small-batch customization?

Absolutely. We provide Large-scale wholesale Wood Grain PVC Film and flexible small orders starting at 3,000 meters.

Q3: How does your low-shrinkage film perform compared to European brands?

Our Low-shrinkage Wood Grain PVC Film achieves only 0.3% shrinkage — roughly half of most European brands — eliminating edge lifting and deformation.

Q4: Can you provide environmental test reports?

Yes. All products are certified under ROHS, REACH, and ISO9001, and we can supply complete compliance documentation.

Q5: What is your typical lead time?

Standard products ship within 7–15 days, and customized orders within 20 days.

6. Conclusion: China’s Full-Chain Manufacturing Power

In today’s global race for greener, more reliable, and more cost-efficient materials, China’s Nature Wood PVC Decorative Film manufacturers are reshaping market expectations. From raw PVC powder to finished decorative film, from quality control to international logistics, Jiangmen Xiete demonstrates that “Made in China” now means innovation, consistency, and partnership value.

When global buyers look for dependable, eco-certified, and cost-effective decorative film,

Xiete stands ready — powered by Our proprietary base material,

delivering Stable supply of Wood Grain PVC Film, and

leading with Large-scale wholesale Wood Grain PVC Film capability.

📞 Contact Us

Jiangmen Xiete New Materials Technology Co., Ltd.

📍 Address: Jiangmen City, Guangdong, China

🌐 Website: www.xtdecorfilm.com

📧 Email: erica@xtwallpaper.com

📦 Product Lines: Wood Grain PVC Film / Marble Film / Cement Grey Series / Fabric Film / Outdoor Decorative Film