The Hidden Standard of Global Hotel Design – The Power Behind Uniform Luxury

In today’s global hospitality industry, leading hotel brands such as Hilton, Marriott, and Accor face a subtle yet critical challenge: how to maintain material consistency across dozens of hotels worldwide. From Dubai’s skyscraper suites to Paris’s boutique hotels, even the slightest color deviation in a wall panel or metallic surface can distort brand identity. This challenge has given rise to a new generation of partners—manufacturers capable of delivering flawless precision and global consistency. Among them, China’s Metallic PVC Decorative Film suppliers have quietly become the “invisible champions” behind many of the world’s luxury spaces.

China’s Value-Based Manufacturing System: Scaling Precision and Trust

1. Scale and Quality Consistency

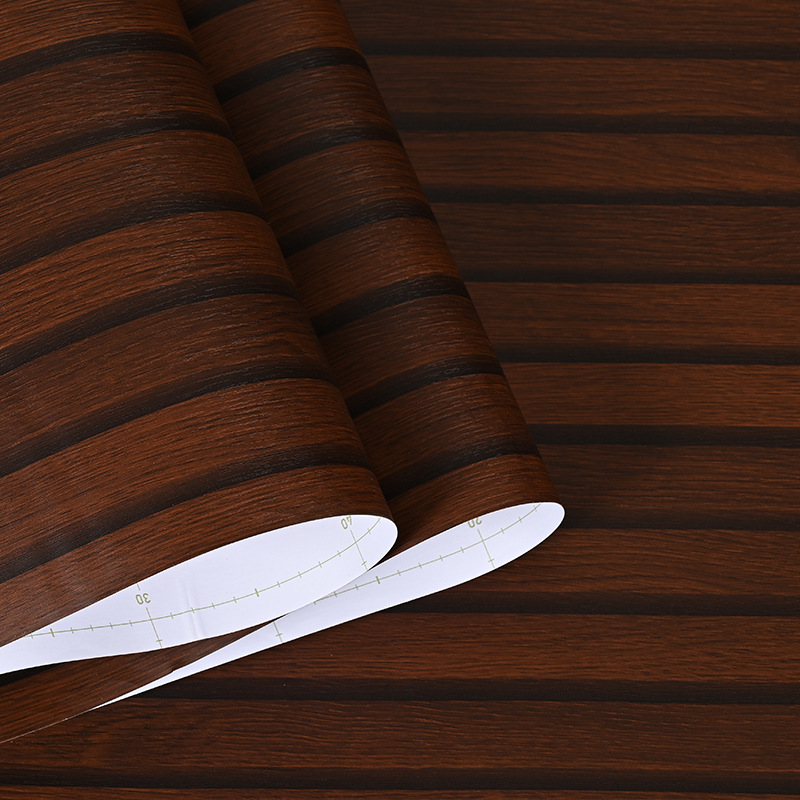

Behind every successful Global PVC Decorative Film lies a deeply integrated production system. Jiangmen Xiete operates fully automated extrusion, coating, and lamination lines that ensure every meter of film maintains the same gloss, texture, and tone.

Color variation—often the bane of global rollout projects—is strictly controlled. Using color spectrophotometers, the factory guarantees a ΔE value below 0.5, ensuring even bulk shipments retain identical hues. Durability, tensile strength, and flame retardancy are tested through abrasion resistance machines and aging simulators, guaranteeing long-term performance in high-traffic environments such as hotels and elevators.

“Our production doesn’t stop at output—it’s about precision and repeatability,” said a senior engineer from Xiete. “Each roll of our Hotel Grade PVC Decorative Film represents the same promise, whether it’s for Shanghai or Stockholm.”

2. Project Coordination and Agile Response

In the era of fast-paced hospitality development, responsiveness defines partnership value. Jiangmen Xiete has established a strategic service model tailored for international hotel chains, combining real-time order tracking, sample verification, and logistics transparency.

From concept to container, the company can turn design samples into mass production within 15 working days—crucial for tight renovation schedules. The Strategic PVC Decorative Film service team provides continuous updates through an online dashboard, allowing clients to monitor production status, shipment progress, and quality documentation in real time.

This agility has proven vital for last-minute refurbishment projects, ensuring that even large-scale hotel rollouts meet deadlines without compromising quality.

3. Co-Development and Global Compliance

For international hotel projects, compliance is non-negotiable. Jiangmen Xiete collaborates closely with chemical engineering partners to design Fire Retardant PVC Decorative Film solutions that meet EU CE, RoHS, and REACH standards, as well as US NFPA 701 requirements.

Each film undergoes rigorous third-party testing, and a full certification dossier is provided to clients to streamline global project approvals.

Furthermore, Xiete’s R&D team develops custom coatings that enhance UV resistance and antibacterial performance—key for Hotel Grade PVC Decorative Film installations in humid or high-traffic environments.

The Strength of “Intelligent Manufacturing in China”

At the heart of Xiete’s success is its blend of engineering precision and creative flexibility. The company has invested heavily in automated color-matching systems, German coating technology, and eco-solvent formulations that drastically reduce VOC emissions.

This dedication to sustainability has positioned the brand as a forward-thinking leader in the Global PVC Decorative Film market.

Over the past five years, the company’s decorative films have been used in more than 80 hotel and commercial projects worldwide—including an iconic beachfront resort in Thailand and an international airport lounge in Dubai—each demonstrating how innovation, reliability, and sustainability can coexist in perfect harmony.

Industry Analysis Table

| Parameter | Hotel Grade PVC Film | Real Metal Sheets | Paint or Spray Coating |

| Cost Efficiency | ★★★★★ | ★★☆☆☆ | ★★★☆☆ |

| Installation Speed | ★★★★★ | ★★☆☆☆ | ★★★★☆ |

| Color Consistency | ΔE < 0.5 | ΔE 1.2~2.0 | ΔE 1.5~2.5 |

| Fire Resistance (A/B Class) | Certified | Conditional | Variable |

| Maintenance & Durability | Easy to clean, anti-fingerprint | Requires polishing | Prone to fading |

| Sustainability (VOC Emission) | <10g/L | N/A | >100g/L |

| Customization Flexibility | Unlimited textures/colors | Limited | Moderate |

Client Success Story: European Hotel Group’s Strategic Shift

A European hotel management company once faced a major dilemma—rising renovation costs and inconsistent finishes across its global properties. After evaluating suppliers from Italy, South Korea, and China, the group selected Jiangmen Xiete as its Strategic PVC Decorative Film partner.

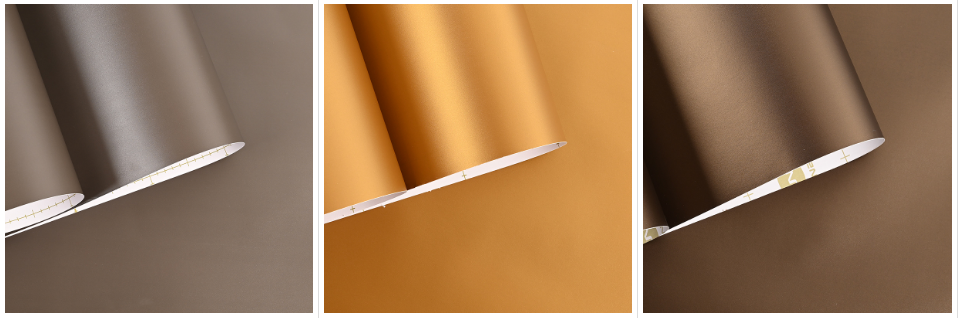

Through collaborative product development, Xiete provided Metallic PVC Decorative Film tailored to match the group’s signature brushed champagne tone. Within a year, project costs dropped by 35%, while project consistency and approval speed increased by 40%.

“Partnering with Xiete was more than cost-saving—it meant reliability, certification support, and global consistency,” said the procurement director.

FAQ – Everything You Need to Know About Hotel-Grade PVC Films

Q1: Are these films suitable for outdoor use?

Yes. The Global PVC Decorative Film series includes UV-resistant and weatherproof options for façades, outdoor signage, and balcony cladding.

Q2: Can the film be installed over existing surfaces?

Absolutely. Hotel Grade PVC Decorative Film can be applied directly over wood, metal, glass, or composite panels—no demolition required.

Q3: What fire standards do they meet?

Xiete’s Fire Retardant PVC Decorative Film complies with both A2 and B1 flame-retardant standards, making it suitable for hotel corridors, elevators, and public areas.

Q4: How customizable are the designs?

Each Metallic PVC Decorative Film can be tailored in texture, gloss, and metallic tone (brushed steel, champagne gold, rose copper, etc.) to align with brand guidelines.

Q5: What is the minimum order quantity (MOQ)?

MOQ varies by specification, generally 300 meters per color, with flexible sampling options available.

Conclusion: The Strategic Value of a Trusted Manufacturing Partner

In an increasingly competitive global hospitality market, brand consistency and material integrity are no longer optional—they are strategic imperatives.

By combining technical innovation, certified quality, and customized global service, Jiangmen Xiete New Materials Technology Co., Ltd. has proven that China’s Metallic PVC Decorative Film industry is not just keeping pace with the world—it is quietly defining its standards.

Whether for a hotel renovation in Dubai or a new build in Paris, Xiete ensures every surface tells the same story of excellence, elegance, and reliability.

Call to Action:

Book a virtual factory tour today and experience how the future of Hotel Grade PVC Decorative Film is designed, produced, and perfected in China.