How is PVC Decorative Film Laminated onto Furniture?

PVC decorative film is a material widely used for furniture surface decoration. It is bonded to panels (such as MDF, particle board) through a vacuum exhaust process, forming a smooth, wear-resistant, and waterproof surface effect. Below is the complete lamination process:

I. Preparation before Laminating

Substrate Treatment

Panel Selection: Commonly uses Medium Density Fiberboard (MDF) or particle board, requiring a flat surface free of burrs.

Sanding/Polishing: Treat the substrate surface with sandpaper or a sander to ensure no unevenness or dust.

PVC Decorative Film Selection

Thickness: Typically 0.15~0.5mm, with 0.2~0.3mm commonly used for furniture.

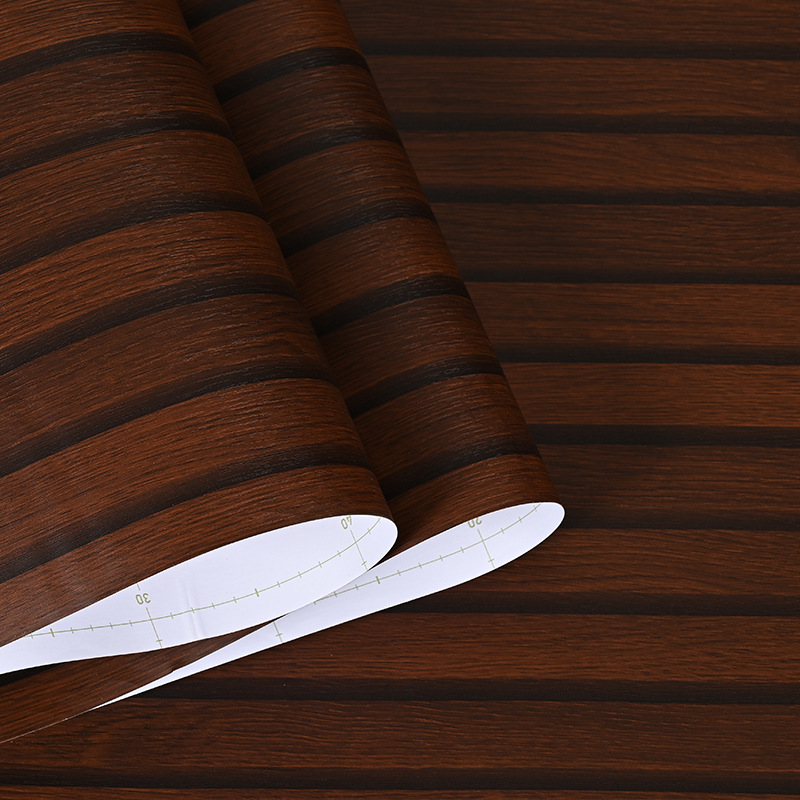

Texture & Color: Wood grain PVC Decorative Film, marble grain, cabinet pvc film,solid colour peel and stick PVC Decorative wallpaper, etc., selected according to design requirements.

Adhesive Layer Type: Our Self Adhesive PVC Decorative Film has a pre-applied adhesive layer on the back and can be directly bonded.

II. Core Laminating Process Flow

Cleaning & Dust Removal: Thoroughly remove surface impurities to avoid air bubbles after film application.

Spreading the Film & Positioning

Spread the furniture PVC Decorative Film flat onto the panel, reserving a 3~5cm margin around the edges (for ease of subsequent trimming).

Use a ruler for preliminary measurement to prevent shifting.

Adhering, Smoothing, and Trimming

Adhere the film.

Use a squeegee to smooth the surface.

Use a manual trimming knife to remove the excess film material.

Inspection Items:

Is the surface flat, free of air bubbles, and free of scratches?

Are the edges and corners tightly fitted with no edge lifting?