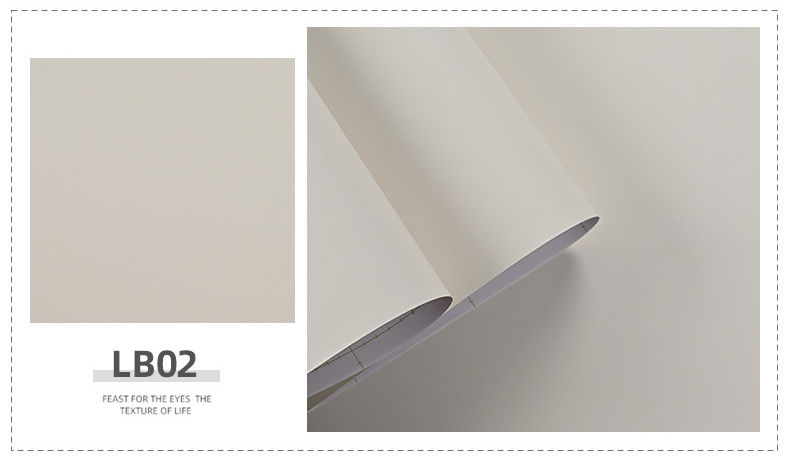

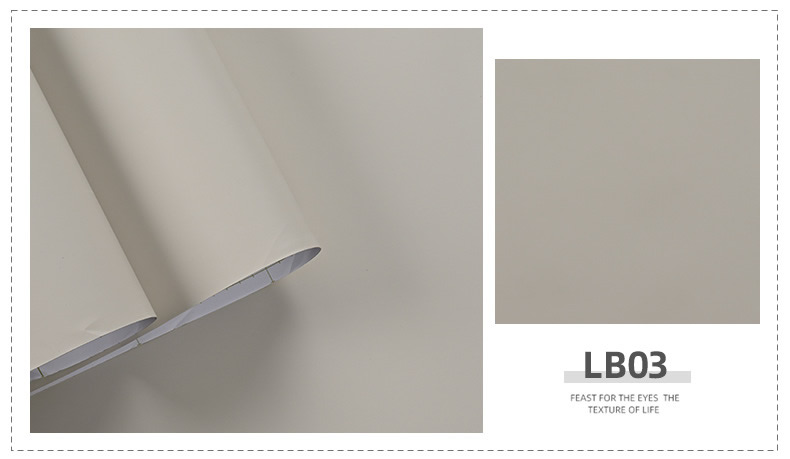

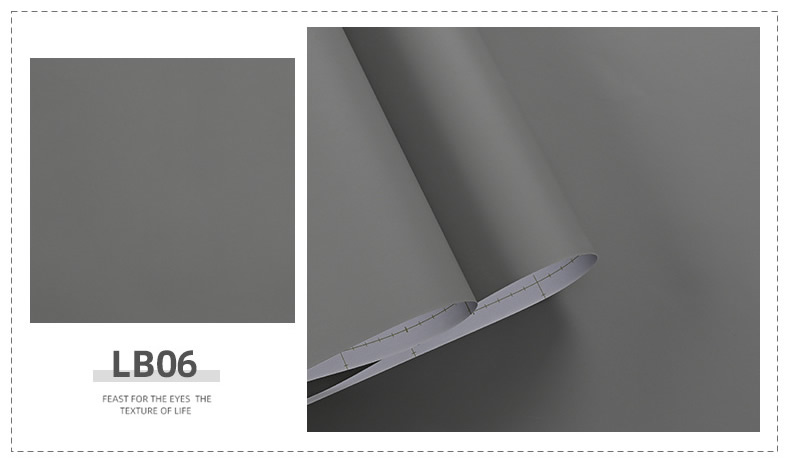

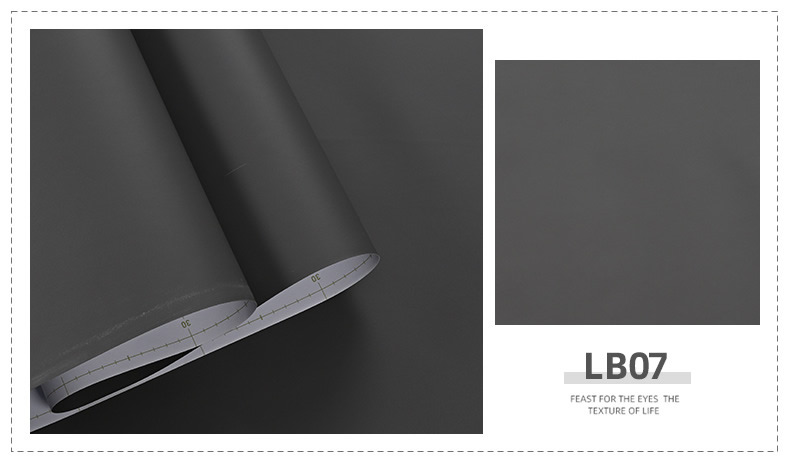

LB Series excimer matte soft touch PVC decorative film, as with the LA series, using excimer technology, thereby creating a unique soft touch on the surface. And on the basis of LA series products, a matte treatment is applied to the product surface, making the color look duller but not affecting its smoothness.

The core competitiveness of the LB series decorative film lies in the deep integration of excimer technology and surface sandblasting treatment. The combined application of these two technologies not only solves the shortcomings in the surface performance of traditional PVC films but also endows the product with a unique visual and tactile experience. It can effectively resist the penetration of oil stains and water marks from daily use — even stubborn stains such as soy sauce and cooking oil can be restored to cleanliness after wiping with a wet cloth, completely solving the pain point of traditional decorative films being 'dirty and difficult to clean'. In the same time, It is not prone to fading or yellowing, ensuring a durable and stable decorative effect.

The surface sandblasting treatment further upgrades the sensory experience.The texture is smooth and not rough, which can effectively prevent fingerprints from remaining. It also creates a soft diffuse reflection effect under light, reducing visual fatigue caused by direct strong light exposure. This matte texture can also adapt to various interior design styles such as modern minimalist, industrial, and luxury, allowing surface decoration to go beyond the single smooth feel, adding more possibilities to space design.

1. Base material: 140 micron thick PVC material

The film body substrate uses high-quality PVC material with a thickness of 140 microns, which is considered to be mid-to-high-end in the industry. This thickness ensures that the film body maintains its stiffness (resistant to wrinkling and deformation, facilitating positioning and cutting during installation), while also providing sufficient flexibility (adaptable to curved panel materials with an arc radius not exceeding 5mm, such as curved cabinet door panels and decorative arcs, avoiding cracking or warping). Additionally, this PVC material has undergone special anti-aging treatment, maintaining stable performance within the temperature range of -20°C to 60°C. It can effectively resist the effects of temperature changes, whether in indoor decoration in cold northern regions or applications in humid southern environments, thereby extending the product's service life.

2. Glue: Eco-friendly oil-based glue

The adhesive layer on the back of the film body uses an environmentally friendly oil-based glue. Compared to traditional water-based adhesives, it has advantages such as high bonding strength , less tendency to develop hollowing or peeling after application, and stable adhesion even after long-term use; good temperature resistance (capable of withstanding short-term high temperatures up to 80°C, and not easily delaminating when in close proximity to radiators or air conditioning vents); strong adaptability to construction conditions (can be applied normally within a temperature range of 5°C to 35°C without the need for additional heating or cooling, reducing environmental constraints on construction).

At the same time, this oily glue has passed the SGS environmental certification, with a volatile organic compound (VOC) content of ≤100g/L, far below the industry average. During the construction process, there is no obvious irritating odor, which reduces the impact on the health of construction workers and can also shorten the ventilation time after renovation to allow customers to move in or use the space more quickly.

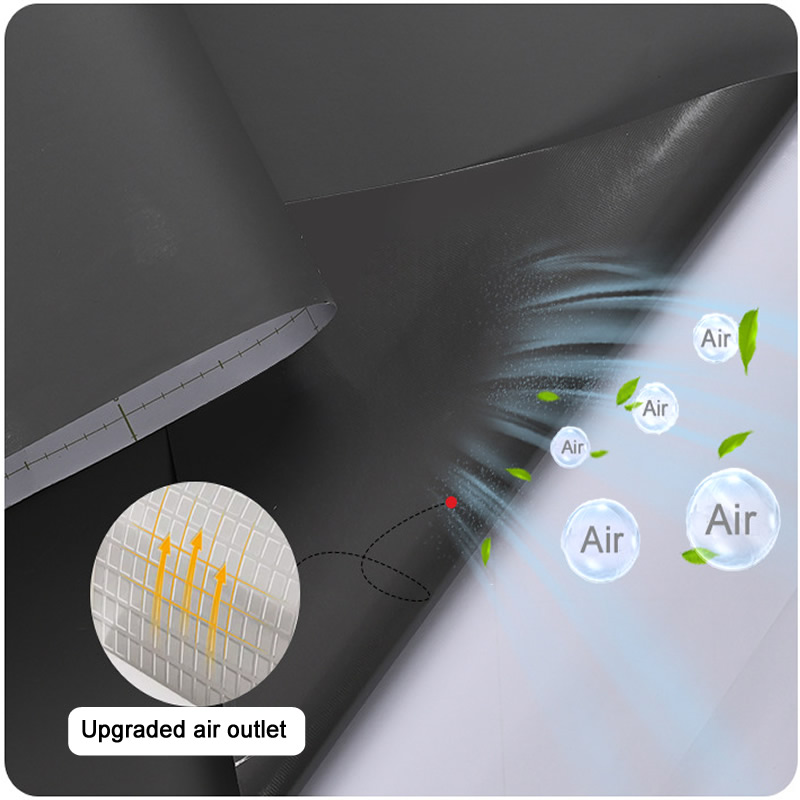

3. Base Paper: 120g with air guide groove design

The base paper serves as the protective carrier for the film body, using a 120-gram high basis weight release paper. The paper has high stiffness and can effectively protect the matte texture on the surface of the film body from being scratched or worn. At the same time, it facilitates the peeling operation during construction (the peel force is uniform and there is no risk of base paper breakage or residue).

More importantly, the base paper surface is designed with dense air guide grooves (with a width of 0.2mm and spacing of 2mm, arranged in a grid pattern). This detail design is key to solving construction difficulties — during the pasting process, air can be quickly discharged through the air guide grooves, preventing bubbles from forming between the film body and the board material, significantly reducing construction difficulty. Even novice construction workers can easily achieve bubble-free pasting with the assistance of the air guide grooves, improving construction efficiency (compared to decorative films without air guide grooves, construction efficiency can be increased by more than 20%), and reducing rework costs due to bubble issues.

Wood-based panels

Including solid wood particle boards, medium density fiberboard (MDF), multi-layer solid wood boards, and plywood, are the most commonly used types of panels in home decoration. This decorative film has excellent adhesion to wood-based panels, and after application, it can closely adhere to the surface of the panels, effectively covering minor defects on the surface of the panels (such as slight scratches, color differences, etc.), while protecting the panels from moisture damage, preventing wood-based panels from molding and warping due to dampness. It is suitable for decorating home cabinet bodies such as wardrobe doors, kitchen cabinets, bookshelf side panels, and TV cabinet panels, as well as for wooden wall decorative panels and wooden ceiling designs.

Metal and plastic sheets

For non-wooden materials such as aluminum alloy plates, stainless steel plates (matte finish), and ABS plastic panels, this decorative film can also be stably bonded through environmentally friendly oil-based adhesives without chemically reacting with metals or plastics, avoiding corrosion of the material or discoloration of the film. It is suitable for metal cabinet door panels, plastic decorative lines, aluminum alloy skirting boards, and appliance housings (such as refrigerator side decorations, washing machine top panels, etc.), providing more style options for the decoration of non-wooden materials.

LB Series excimer matte soft touch PVC decorative film, with its diverse advantages, can be widely used in home decoration, commercial spaces, public facilities, and other scenarios to meet the decorative and functional needs of different settings.

Our Main Products Selection

—

A2 flame retardant film, elevator metallic film, outdoor film, wood grain film, marble film, solid color film, cement gray film, soft touch film, fabric texture film and glue-free electrostatic film, etc.

|

|

|

|

|

|

|

|

|

|

|

|

|

| Excimer technology with matte surface treatment | 140microns PVC material,Waterproof, oilproof, easy to clean | Upgraded air outlet grille, easy to install |

Our Product Application Display

For Home decoration, Hotel, hospital, office, shopping mall, exhibition hall, elevator, ship, high-speed rail, indoor decoration and so on.

Wood Grain PVC Decorative Film

Marble Grain PVC Decorative Film

Elevator PVC Protective Film

Solid Color PVC Decorative Film

A2 Fireproof PVC Decorative Film

Outdoor PVC Decorative Film

Fabric Design PVC Decorative Film

LS Metallic PVC Decorative Film

Soft Touch PVC Decorative Film

About Xiete New Materials

Jiangmen Xiete New Materials Technology Co., Ltd.

Our Factory and Team

Product Production Packaging

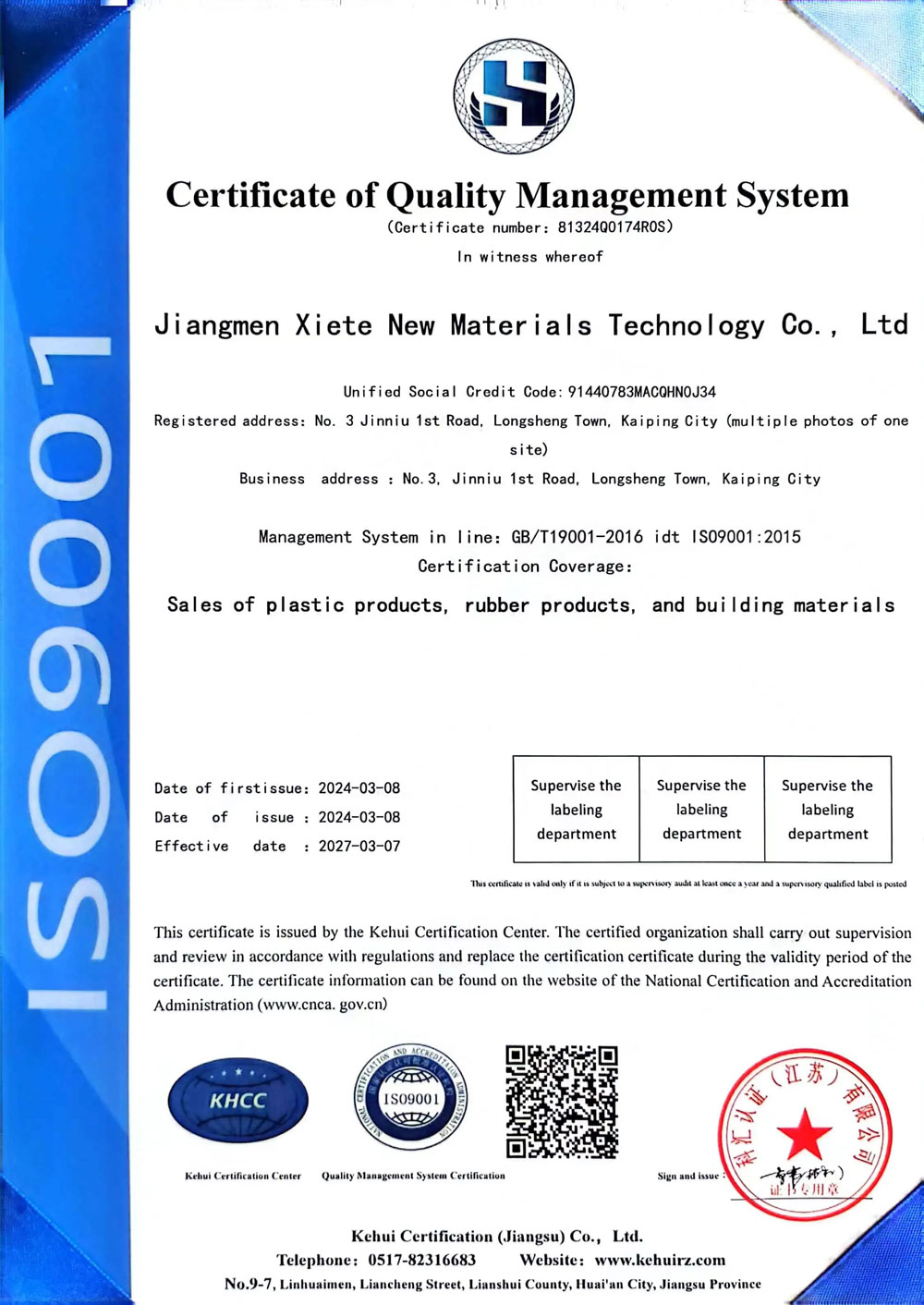

Product Quality Certification

1S09001 Certificate

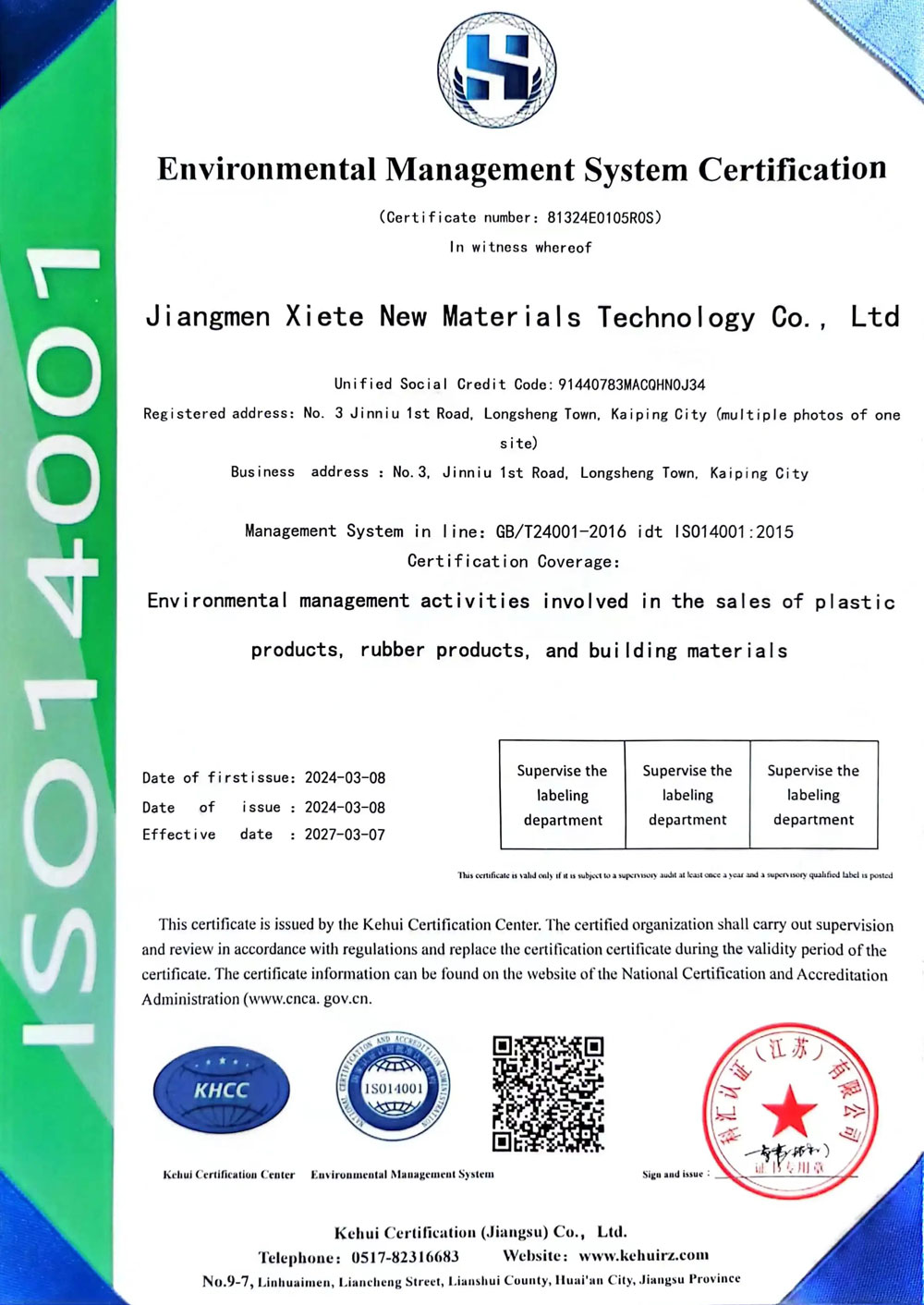

IS014001 Certificate

FAQ

Q1:Are you factory?

A:Yes,we are factory, we have been producing peel & stick PVC film around 20 years.We have a very mature production technology and strict quality control system.

Q3: Do you provide free samples?

A: Yes, we offer free samples. We can even offer free shipping to countries that are close to us. You can select the items which you like on our website and send us.

Q4:Could you send me all your catalogue and price list?

A: As we have many designs,it is really too hard for us to send you all our catalogue and price list.Please inform me the items, size and packages you interested in, so we can offer you the price list for your reference.

Q5:Could you make my OEM designs?

A:Yes, we can. You can make your graphic pattern, carton and logo designs.OEM is available.

Q6. What is your MOQ?

A: Normally the MOQ is 500 meters. But almost of our products are in stock, so we accept small quantity, contact us for more details.

Q7:Lead Time?

A:Our Daily Capacity is arround 160,000meters, so the lead time is very short. (1*20GP is 1-3days, according to the production scheduling),We will make the delivery as soon as possible with the guaranteed quality.

Q8:Can I be your distributor or agent in my country?

A:Yes, we have two brands, Kinnard and SHQ for you to choose.