As sustainability becomes the defining theme of modern living, the interior design and construction industries are undergoing a profound transformation. Consumers are no longer satisfied with visually appealing materials alone—they want surfaces that are safe, environmentally responsible, and aligned with global green-building standards. Among the emerging solutions, Eco-Friendly PVC Film Design has rapidly become a key driving force in the future of home and commercial decoration.

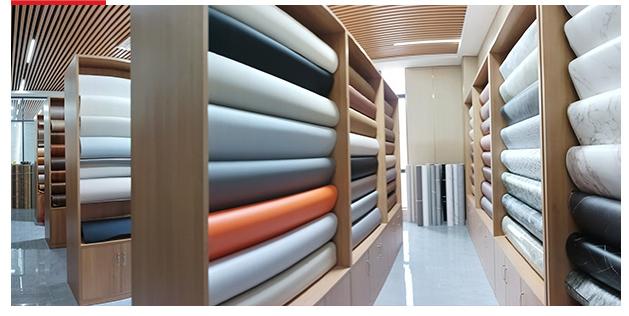

Jiangmen Xiete New Materials Technology Co., Ltd., headquartered near Guangzhou, has long been a leading innovator in the PVC decorative film industry. Through its SHQ and Kinnard brands, the company has expanded from classic wood grain and marble textures to advanced outdoor films, antibacterial finishes, A2/B1 fire-retardant materials, and now a new generation of sustainable surface solutions. These innovations include Sustainable Decorative Film, Green Building Materials, Biobased PVC Membrane, and advanced Recyclable Design Film technologies, setting new benchmarks for environmentally conscious design.

1. Market Pain Point Analysis: Why the Industry Must Evolve

Environmental Controversies Around Traditional PVC

For decades, conventional PVC products have been criticized for their environmental footprint. Concerns around plasticizer toxicity, recyclability limitations, and carbon-intensive production processes have pushed the industry toward greener alternatives such as Eco-Friendly PVC Film Design.

Growing Consumer Demand for Health-Safe Materials

As home buyers become more educated, interest in low-VOC, antibacterial, and non-formaldehyde materials skyrockets. Developers seeking to differentiate themselves increasingly specify Sustainable Decorative Film solutions, recognizing their importance in healthier living environments.

Design Industry’s Sustainability Pressure

Green certifications, carbon-reduction goals, and international regulations compel architects and builders to adopt Green Building Materials. This shift accelerates the transition toward Biobased PVC Membrane formulations and scalable Recyclable Design Film systems.

2. Technological Innovations Shaping the Future

Breakthrough 1: Advancements in Biobased PVC

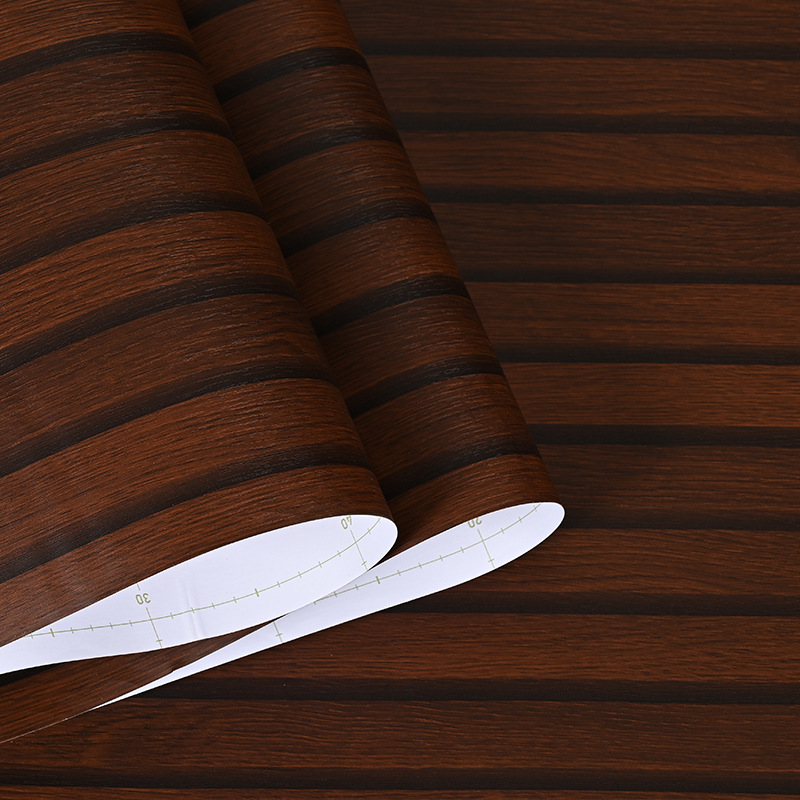

Modern Biobased PVC Membrane technology replaces a portion of fossil-derived components with renewable plant-based alternatives. These films not only reduce carbon emissions but also integrate seamlessly with high-performance decorative applications.

Breakthrough 2: Phthalate-Free Plasticizer Systems

Health-focused research led to the development of phthalate-free, food-grade plasticizers that enhance flexibility without compromising safety. This improvement directly strengthens the market position of Eco-Friendly PVC Film Design and Sustainable Decorative Film.

Breakthrough 3: Circular Recycling Systems

To support global recycling initiatives, leading manufacturers are building closed-loop programs that transform old films into new Recyclable Design Film variants. These systems dramatically reduce waste and align with the future roadmap for Green Building Materials.

3. Design Application Case Studies

Case 1: Green Building Certification Projects

In large-scale public spaces such as government complexes and academic institutions, Green Building Materials incorporating Sustainable Decorative Film have been essential in achieving certifications like LEED and WELL.

Case 2: Healthy Residential Environment

Developers designing modern wellness apartments increasingly rely on Eco-Friendly PVC Film Design for walls, cabinetry, and door surfaces. These films reduce indoor pollutants and integrate perfectly with natural décor themes.

Case 3: Commercial Sustainable Design

Retail stores and hotels have adopted Biobased PVC Membrane finishes to align with their environmental branding while benefiting from high wear resistance and color stability.

In each of these cases, Recyclable Design Film options ensure long-term sustainability even when future renovation cycles occur.

4. Performance Comparison & Environmental Metrics

Environmental and Performance Comparison Table

| Category | Traditional PVC | Eco-Friendly PVC Film Design |

| Raw Materials | 100% petroleum-based | Includes Biobased PVC Membrane content |

| Plasticizers | Often phthalate-based | Phthalate-free, food-grade systems |

| Recyclability | Limited | Supports Recyclable Design Film cycles |

| VOC Emission | Relatively high | Ultra-low VOC, healthier indoor air |

| Application Areas | Standard interiors | Suitable for Green Building Materials projects |

| Durability | Good | Enhanced scratch, stain, and aging resistance |

Independent lifecycle assessments show a carbon reduction of up to 18–35% when switching from conventional films to Sustainable Decorative Film, solidifying these materials as frontrunners in future construction standards.

5. Industry Analysis Table: Trends Driving Sustainable PVC Films

| Trend | Market Insight | Impact |

| Sustainability Mandates | Governments enforcing green-building policies | Increases demand for Eco-Friendly PVC Film Design |

| Material Innovation | Rapid rise of Biobased PVC Membrane technology | Encourages adoption in premium architecture |

| Circular Economy | Growing support for Recyclable Design Film systems | Reduces waste and lifecycle costs |

| Health-Safe Interiors | Low-VOC requirements in homes and hospitals | Boosts use of Sustainable Decorative Film |

| Commercial Greening | Hotels & malls upgrading to eco-materials | Expands market for Green Building Materials |

6. Frequently Asked Questions (FAQ)

Q1: Are sustainable PVC films as durable as traditional ones?

Yes. Many Eco-Friendly PVC Film Design solutions outperform conventional products in scratch resistance, stain resistance, and UV stability.

Q2: What percentage of the film is bio-based?

Depending on the formulation, Biobased PVC Membrane products can replace 10–35% of petroleum components with renewable alternatives.

Q3: Can these films be recycled after removal?

Absolutely. Closed-loop systems are designed for Recyclable Design Film processing, supporting circular economy goals.

Q4: Are they compatible with green building certifications?

Yes. Green Building Materials made with Sustainable Decorative Film often qualify for LEED, WELL, and other environmental credits.

Q5: Can they be used in high-traffic areas?

Definitely. Commercial environments frequently apply Eco-Friendly PVC Film Design due to its robust wear resistance.

Conclusion: A New Chapter in Sustainable Interior Design

The shift toward sustainability is no longer optional—it is the new foundation of modern home and commercial decoration. With advancements in Biobased PVC Membrane formulations, improved recyclability, and safer additive systems, the future of decorative surfaces is being rewritten. Through cutting-edge manufacturing and strong environmental commitments, Jiangmen Xiete’s SHQ and Kinnard brands are proving that beautiful design and ecological responsibility can coexist seamlessly.

Whether through Sustainable Decorative Film, Eco-Friendly PVC Film Design, or next-generation Recyclable Design Film, these materials redefine what Green Building Materials can achieve in shaping healthier, more responsible living and working spaces.

Call to Action

For designers, developers, and distributors seeking eco-conscious surface solutions that combine style, durability, and environmental responsibility, Jiangmen Xiete welcomes you to request samples or begin custom production.

Join the movement toward sustainable interior innovation—start with greener materials today.